- Home

- Machines

- Warping Machines

- KGA163S Sectional Warping Machine (Filament Yarns)

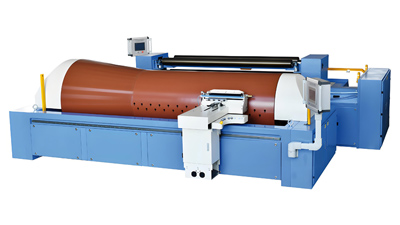

KGA163S Sectional Warping Machine (Filament Yarns)

This sectional warping machine model features digital controls and a well-integrated structure designed for consistent tension and smooth yarn winding. It’s particularly suited for small-batch sampling and multi-variety production, offering a cost-efficient solution for sectional warping of fine denier and microfiber filament yarns, including sizing applications.

Features

- The beaming unit, leasing reed stand, yarn guide frame, and creel are all fixed in position, maintaining consistent alignment throughout the warping process.

- Yarn alignment stays centered from start to finish, helping ensure uniform tension across the warp sheet and consistent winding quality.

- The warping table moves backward automatically via servo control in sync with drum rotation, maintaining a consistent distance between the reed and yarn surface, adjustable to reduce spreading, especially useful for high-density or heavyweight fabrics.

- The braking system combines pneumatic and hydraulic functions, offering smooth and precise control while remaining clean and reliable.

- The beaming section features a dual-layer guide roller design with hydraulic control for upper and lower beam operation. An optional triple-roller tensioning system can be configured if needed.

Machine specifications

| Working width | 2000-3600 mm |

| Beam flange diameter | ≤1000 mm, ≤800 mm |

| Warping speed | 0-600 m/min, 0-700 m/min |

| Beaming speed | 0-100 m/min, 0-200 m/min |

| Deviation of linear speed (warping & beaming) | ≤±2% |

| Braking distance | ≤3 (at a linear speed of 500m/min) |

| High beaming tension | ≤8000 N, ≤10000 N (at a beaming speed ≤50m/min) |

| Low beaming tension | ≤3N, ≤50N |

| Drum diameter | 1026 mm |

| Cone length | 1360 mm, 1010 mm |

| Cone angle | 9°, 7.125° |

| Section traverse speed | 0.001-9.999 mm/r (stepless) |

| Section traverse accuracy | ±0.01 mm |

| Distance between reed and drum | Constant (adjustable) |

| Spindle space | 290×290 mm (filament yarn) 250×250 mm (wool, cotton and blended yarn) |

| Number of bobbins | 420 pcs (wool, cotton and blended yarn) 480 pcs (filament yarn) |

- Air Jet Loom

- Water Jet Loom

-

Quick Link

-

Contact Us

- NO.84 Huan Taibei Road, Wangtai Street, Huangdao District, Qingdao,China.

- Ellen Zhou

- +86-18353204512

- sweeti.e@163.com