- Home

- Machines

- Warping Machines

- Warping Creel

Warping Creel

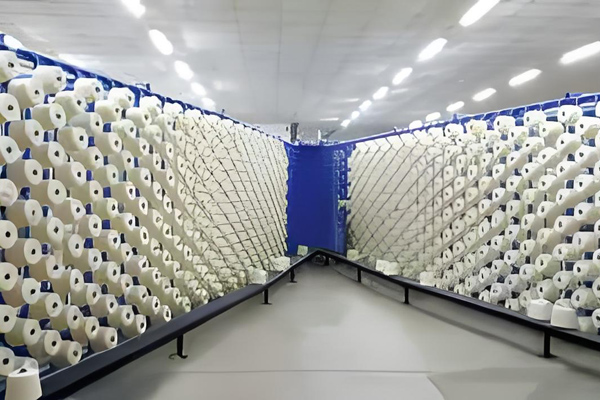

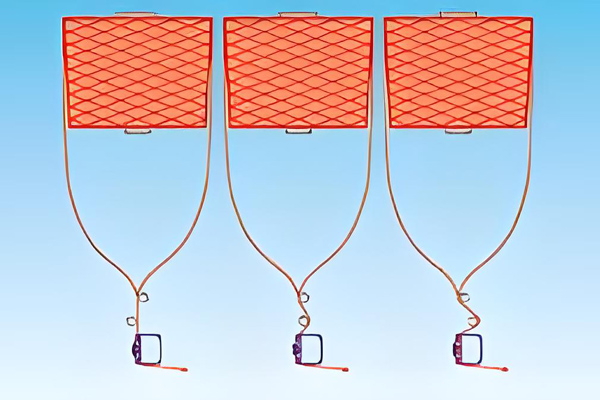

Our upgraded warping creels feature a double-disc without vertical columns that handles a wide variety of yarn types. It is suitable for different warping processes, including sectional and batch warping. Available in rotating rectangular, mobile frame, and compact V-shaped configurations, offering flexibility for various production setups while ensuring consistent and reliable yarn feeding.

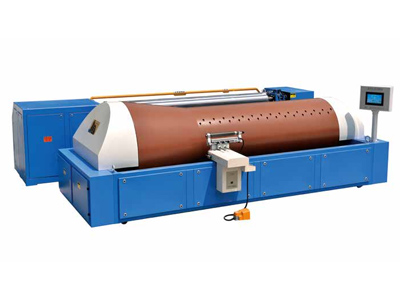

Rewind rectangle bobbin creel

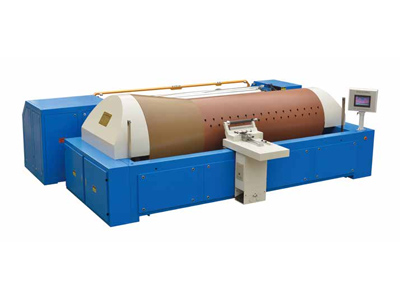

Rewind rectangle bobbin creel Rewind V-shaped bobbin creel

Rewind V-shaped bobbin creel Fixed creel

Fixed creel Double disc non-pillar rotary tensioner

Double disc non-pillar rotary tensioner

This V-creel is commonly used with sectional warping machines used for short-staple yarns. Its compact frame and open yarn path, free of intermediate guides between the creel and the reed, make it ideal for delicate fibers that are sensitive to friction. The creel design supports low-tension, high-speed unwinding, helping minimize tension variations and yarn breakage during warping. Yarn packages are arranged in a staggered V-formation to maximize space efficiency. A standby set of bobbins can be placed inside the V-structure for quick replacement, which shortens downtimes and streamlines operation. This creel setup is particularly suitable for high-speed warping processes.

- Bobbin replacement is done by inserting new packages into the creel, followed by automatic group exchange via a motor-driven circulating chain.

- The V-shaped dual creel wing layout of the creel uses external yarn guiding, allowing yarn to move freely without any intermediate contact elements, minimizing friction.

- Each spindle is equipped with a non-contact photoelectric yarn break detector that accurately monitors even fine, low-tension yarns.

- Break indicators are installed for each spindle and each row. The control box displays the exact location of yarn breaks by row and layer, making it easy for operators to respond quickly and maintain productivity.

- A yarn count preview function allows operators to verify the total number of yarns before warping begins. Warping can only proceed once the preview matches the required settings.

- Yarn tension differences between the front and rear creels are reduced by adjusting the wrap angle with a pre-tension bar, helping to minimize individual yarn tension variation. The bar also prevents tangling when restarting after a sudden stop during high-speed unwinding.

- Each spindle features a yarn clamping device that applies gentle braking at start-up and stop points, preventing yarn slack during acceleration or deceleration.

- The yarn cutting system operates electrically for clean and efficient trimming.

- A periodic air-blowing unit is included for dust removal.

- An independent control box is mounted on the front side of the creel for easy operation and monitoring.

This patented device simplifies the yarn changeover process by automatically cutting all yarns across the creel in a single pass. Fitted with an electric blade, the cutter moves smoothly along the creel, trimming all yarns simultaneously without requiring manual intervention.

Consistent and low yarn tension throughout the process helps maintain yarn integrity and reduces breakage. Since the yarn moves freely without excessive pulling, each warp end remains in optimal condition. This minimizes stress on the fibers, which not only improves warping results but also benefits subsequent sizing and weaving processes by ensuring better fabric quality and fewer disruptions.

During batch changeover or bobbin replacement, there’s no need to cut or tie the yarn. Bobbins can be directly mounted onto the spindle, making the process faster and easier for the operator.

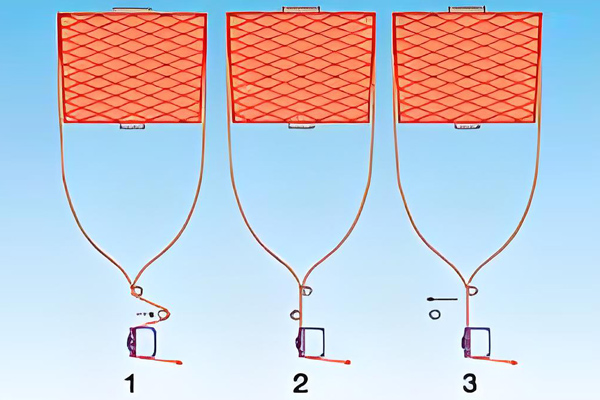

The automatic pre-tensioner helps prevent slack yarn that could cause machine stoppages. It adjusts its position throughout each stage of the warping process to maintain optimal tension:

- At startup, it shifts to its maximum position to eliminate slack.

- During normal operation, it maintains a stable position to keep yarn tension consistent.

- When the machine stops, it fully releases, allowing easy access to the bobbins for handling or replacement.

The pretensioners installed by our automatically compensate the thread tension differences occurring due to the variation in thread length from the rearmost to the foremost package, permitting a uniformthread tension and winding over the entire warp width. The automatic pretensioner is set so that a corresponding wrap compensates the difference in tension between the front and rear threads.

| Column distance (mm) | Row distance (mm) | Max. diameter of yarn package (mm) | Number of row (mm) | Number of spindle | |||||||||||

| 240 | 240 | 230 | 9 | 504 | 576 | 648 | 720 | 792 | 864 | 936 | 1008 | 1080 | 1152 | 1224 | 1296 |

| 270 | 255 | 8 | 448 | 512 | 576 | 640 | 704 | 768 | 832 | 896 | 960 | 1024 | 1088 | 1152 | |

| 305 | 265 | 7 | 392 | 48 | 504 | 560 | 616 | 672 | 728 | 784 | 840 | 896 | 952 | 1008 | |

| 350 | 278 | 6 | 384 | 432 | 480 | 528 | 576 | 624 | 672 | 720 | 768 | 816 | 864 | ||

| 435 | 305 | 5 | 320 | 360 | 400 | 440 | 480 | 520 | 560 | 600 | 640 | 680 | 720 | ||

| Number of column | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | 64 | 68 | 72 | |||

| Column distance (mm) | Row distance (mm) | Max. diameter of yarn package (mm) | Number of row (mm) | Number of spindle | |||||||||||

| 320 | 240 | 230 | 9 | 378 | 432 | 486 | 540 | 594 | 648 | 702 | 756 | 510 | 864 | 918 | 972 |

| 270 | 260 | 8 | 336 | 384 | 432 | 480 | 528 | 576 | 624 | 672 | 720 | 768 | 816 | 864 | |

| 305 | 295 | 7 | 336 | 378 | 420 | 462 | 504 | 546 | 588 | 630 | 672 | 714 | 756 | ||

| 350 | 340 | 6 | 324 | 360 | 396 | 432 | 468 | 504 | 540 | 576 | 612 | 648 | |||

| 435 | 365 | 5 | 300 | 330 | 360 | 390 | 420 | 450 | 480 | 510 | 540 | ||||

Rotating V-creels are used during the warping process to hold yarn packages in place. Their V-shaped configuration enables a compact layout and efficient space usage, which is ideal for short fiber warping systems. The design supports smooth unwinding and stable yarn tension, contributing to better warping quality.

Oil damping tensioner

Oil damping tensioner  Yarn tensioner with 2 posts

Yarn tensioner with 2 posts Yarn tensioner with 3 posts

Yarn tensioner with 3 posts Yarn tensioner with rings

Yarn tensioner with rings

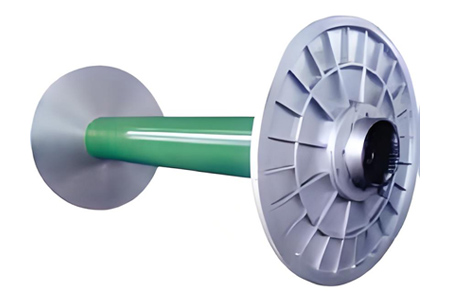

In addition to various types of creel tensioners, we also supply warp beams in different sizes for warping machines, as well as fabric batching rollers used in air jet and water jet looms.

Beam of warping machine ⌀800, ⌀1000, ⌀1250mm

Beam of warping machine ⌀800, ⌀1000, ⌀1250mm Fabric batching roller of air jet loom, and water jet loom

Fabric batching roller of air jet loom, and water jet loom

- Air Jet Loom

- Water Jet Loom

-

Quick Link

-

Contact Us

- NO.84 Huan Taibei Road, Wangtai Street, Huangdao District, Qingdao,China.

- Ellen Zhou

- +86-18353204512

- sweeti.e@163.com